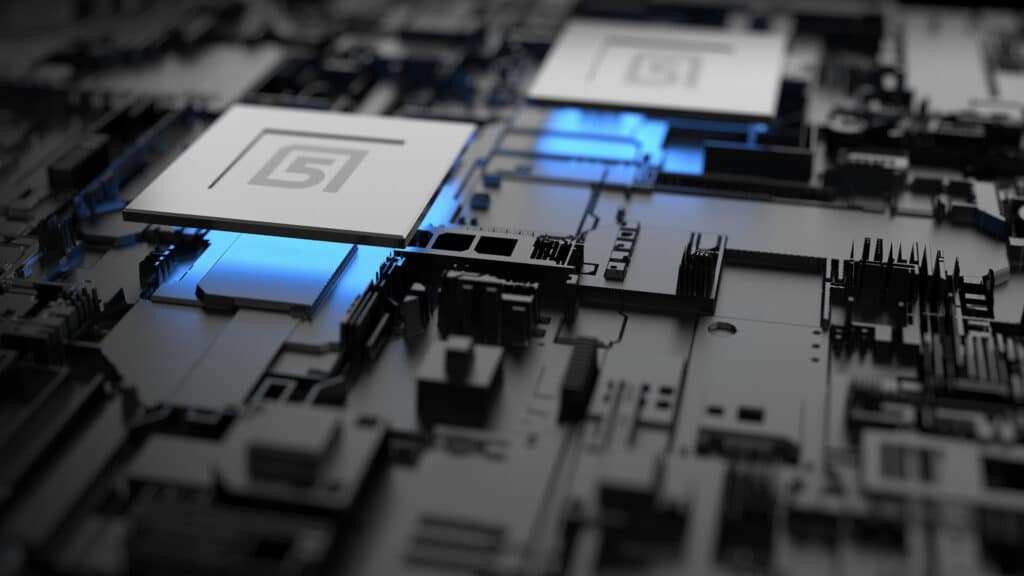

From Apple’s own silicon projects to Google’s Tensor devices and Samsung’s Exynos family of mobile processors, it’s apparent that bespoke silicon is increasingly getting ubiquitous. What had been shaping up as a highly triangular conflict involving Intel, AMD, and Qualcomm has opened out into a landscape with a great deal more competitiveness.

Companies that traditionally made CPUs are now making GPUs and the opposite. Even though I support this development, I’d want to elaborate on why I believe bespoke silicon to be the chip industry’s future, certainly for the coming 20-30 years.

Contents

Different Needs

When comparing Apple to Facebook Microsoft to Amazon to Uber, it’s easy to see that each of these digital behemoths has its own unique approach. Meta, on the other hand, strangely embraces practically any kind of technology, including old devices for a looooong period through text-to-Messenger, whereas Apple retains a firm grasp over their hardware counterparts. The takeaway is that none of these internet behemoths is after providing precisely the same thing to its customers.

Since they all have their own distinct areas of expertise, it makes perfect sense to develop bespoke silicon for each of them. Companies may make their hardware work perfectly with their application if they use bespoke silicon. While I will spend most of my time discussing the operating systems that these companies utilize, I do believe it is vital to acknowledge their common software as we go. In all likelihood, Final Cut Pro performed best on Apple’s proprietary silicon than on any competing platform.

Cost

Even if the widespread production of standard silicon lowers unit costs, specialized silicon still has its uses. When it comes to production costs, it’s probably simpler to maintain something that is once more custom designed and produced in-house; Apple is a wonderful case of this, as they continue to provide software upgrades for their older iPhones for 5+ years after they were first released.

It’s probable that the microchip was built in-house, rather than by a third party who handles most of the firmware, making it economically feasible from the program development point of view. With prices soaring and technological costs rising at an equal rate, it may be in everyone’s best interest to choose personalized silicon over generic, one-size-fits-all alternatives.

Final Thoughts

Consumers shouldn’t expect mind-reading gadgets to suddenly become a reality just because custom silicon is becoming more widely available. Benefits include cheaper initial costs and the possibility of lengthier maintenance over the big scheme of things, as well as individualized solutions that combine exceptionally well with the tech side of production.

Now that I’ve shared my reasoning for why the prospect of bespoke silicon dominating the technological future excites me, I’m eager to get your feedback. Is there a chance that custom silicon may be useful for both the producer and the user, or are we heading toward more exclusive ecosystems? Respond with your ideas and thoughts in the comment section.