Manufacturing and production companies rely on heavy machinery to make goods for their consumers. They operate around the clock, and hence, require daily maintenance.

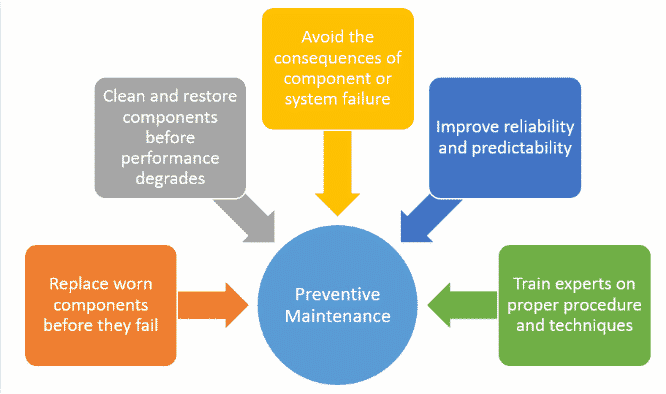

However, these machines can break down at any moment due to both known and unknown reasons. Therefore, companies practice preventive maintenance to downsize the risk of defaults in daily operations.

Contents

What is Preventive Maintenance?

Preventive maintenance, also known as programmed maintenance, is the planning process for foreseen and unforeseen working conditions. This planning results in reducing excess cost, and disruption, and maintaining effective factory management.

For the most part, preventive maintenance is not dependent on technical conditions. However, it is dependent on merchandise or fixed asset production or the general life span of any asset. However, the maintenance team members must facilitate proper cost, backlog, and listing to execute maintenance duties.

Tips to Build a Preventive Maintenance Program

The first step towards applying preventive maintenance is to execute the program. The main aim of large organizations is to ensure that they are functioning effectively.

However, they tend to oversee small problems and focus only on the bigger ones. Ignoring these often lead to issues in the future, significantly increasing the cost of fixing them. Here are some ways to build an effective preventive maintenance program –

Categorize and Set Schedules

To begin with, you need to work out a schedule to manage the tools and calibrate the working requirements. You can do this by studying each element of the tool and its working speed. Thereafter, you can decide whether the job must be measured yearly, mid-yearly, monthly, or weekly.

Sometimes, you can take preventive measures depending on which task you are implementing. For example, you can set a preventive maintenance reminder to check your heating units in late autumn. Accordingly, you can apply it to water motors based on their months of usage.

Moreover, it is mandatory to prepare rough points on multi-planning procedures while also calculating the period required to fulfill preventive maintenance tasks with computerized software. An effective preventive measurement schedule requires the analysis of both inside and outside scenarios to resolve problems quickly.

Prepare a Management List

This list will mostly depend on the size of the organization. Large-scale or small-scale companies require different levels of management techniques. Some important factors include the number of employees, technologies, and industry, among others.

The preparation management list does not maintain the jobs alone; every team member must invest their time and dedicate themselves to it. The willpower to complete the planning will show how much you want the project to give great results.

Every enterprise wants to be free from the mess of paperwork, and preventive maintenance software can lighten up this load for better functioning. Some people also prefer not to come out of their comfort zones to experiment with newer, more effective measures, so you need to convince them to apply these techniques in their daily routines.

One of the last steps regarding preventive maintenance is to find the aim of the project. Do remember that you can’t fix the problems if you can’t calculate them.

Hence, you have to find ways to pay attention to intricate details and plan accordingly. Unplanned working hours may lead you to call employees from holidays which may demotivate them.

Examine, Alter, Re-examine

Working in a business requires constant changes. Hence, it is necessary to examine previous changes and alter your maintenance program based accordingly. This will help you focus on the areas that need more attention, time, and a larger budget than others.

However, creating and executing any preventive maintenance planning and implementation takes a lot of hard work and time. Although you can hire a maintenance team for this task, you should train your employees as well. This can help to cover problems in case of emergencies.

Make it Budget-Friendly

Creating a comprehensive preventive maintenance list can be a time-consuming and exhaustive process. Moreover, it can lead to some pent-up costs as well. These costs may vary based on labor costs, employee salaries, and the size of the organization, among others.

Therefore, it is important to determine your budget and stick to it. This can be done by weighing the problems that are most likely to be caused and working accordingly. Stick to the previous year’s budget and try not to extend unless in case of emergencies.

Using Preventive Maintenance Software

As an alternative, you can use preventive maintenance software with a planning program that can make scheduling a lot easier and more flexible. Most software has helpful tools like automatic work plans, measuring work difficulty, scheduling reminders, and more.

Most problems can be analyzed and evaded with computer-based management software that provides quick solutions. They come with several elements such as merging emails, instant activation, and automatically distributing jobs that help in boosting profitability.

This program is considered just a technique used by the maintenance members. A global maintenance platform showcases the aims of any enterprise and performance with the tools of management, execution, and exploration. This scheduling technique supports the working industry in revamping its capacity and results.

From a future perspective, the idea of maintenance depends on shrinking the problems throughout the cycle of work by examining and implementing preventive measures. Accordingly, it disables any other problems regarding work fixation. Other advantages of using the software include the following –

- Grooms capacity and skills

- Reduce excess paperwork and hand-operated information entry

- Full-fledged work implementation

- Shrink unnecessary problems

- Manage alterations after changes

Conclusion

In summary, preventive maintenance can help to foresee future risks with daily operations and provide a thoughtful plan to overcome them. It is inexpensive, time-saving, and a helpful technique to maintain production efficiency. Moreover, it supports the smooth functioning of your team members and works environment.

The program eases the burden on your shoulders to maintain an effective working order. You can also use work order software that makes the job a lot more effortless by enabling a preventive measurement program with a few clicks. This can lessen the amount of physical work required to do so. If you want to make your life less gloomy and tense-free, then a preventive measure program is the right option for you.