What Are The Advantages Of 3D Printing?

3D printing has been popular in the business for many years, and the benefits it provides have prompted individuals to make the most of this emerging technology.

Table of contents

What precisely is 3D printing and how does it work?

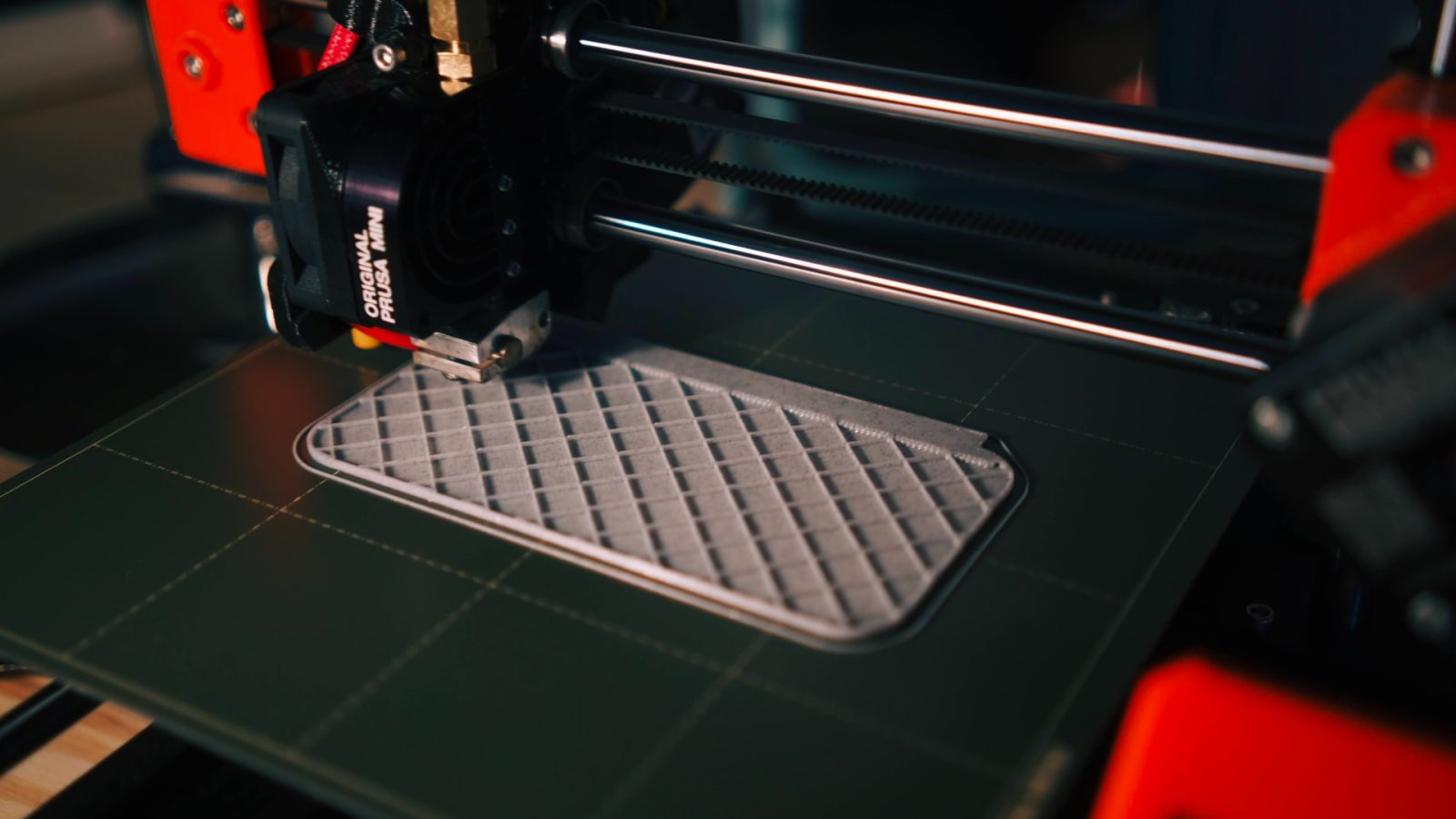

Three-dimensional additive manufacturing, commonly known as 3D printing, is a technique for constructing complex three-dimensional objects from a computer file by stacking different types of material on top of one another in successive layers.

Many benefits of 3D printing over traditional production processes such as subtractive manufacturing and injection molding are being recognized by enterprises across a wide variety of sectors.

- Speed and agility

One of the most significant advantages of 3D printing technology is the ability to produce rapid prototypes. Rapid prototyping is the capacity to design, manufacture, and test a customized component in a short period of time.

It is also known as rapid manufacturing. Furthermore, if changes are required, the design may be altered without impacting the progress of the manufacturing process.

Before the 3D printing business took off, it may take weeks to create a prototype of a product. In every case where a modification was made, the treatment was prolonged by a few weeks. When delivery timeframes are taken into consideration, it is possible that it will take a year or more to finish the production of a product from beginning to end.

- Cost

In terms of cost-effectiveness, 3D printing is the most cost-effective manufacturing technology for short-run production and applications.

Because they require trained machine operators and technicians to run them, traditional prototype technologies such as CNC machining and injection molding necessitated the purchase and maintenance of a large number of expensive machines as well as a high degree of manpower.

- On-Demand Printing

Another advantage of print on demand is that, in contrast to typical production processes, it does not need a large amount of space for inventory storage.

Due to the fact that there is no need to print in quantity unless absolutely required, both space and money are saved.

- Both strong and light components are used.

Plastic is the most widely used 3D printing medium, however metals such as titanium and aluminum can also be utilized in specific applications. Plastics, on the other hand, have the benefit of being far lighter in weight than their metal equivalents. This is particularly significant in industries such as automotive and aircraft, where weight reduction is a priority and better fuel economy may be obtained.

- Obtaining the Most for Your Money

When traditional production processes are used, they might result in bad designs, which then result in shoddy prototypes. For example, consider the process of baking a cake, in which all of the components are combined and blended before the product is cooked. It is possible that the cake will have difficulties such as air bubbles or will not bake fully if the ingredients are not correctly mixed. The same issue might happen when subtractive or injection procedures are used; consistency is not always ensured in either case.

- Quality

Traditional production processes, when combined with bad design, might result in substandard prototypes. Consider the process of making a cake, in which all of the components are combined and blended before the cake is placed in the oven. Air bubbles and underbaking might occur if the ingredients are not completely mixed before baking the cake. As with subtractive and injection techniques, precision is not always ensured when they are used together.

- Environment-friendly practices

This approach is naturally ecologically beneficial due to the fact that it lowers the amount of trash generated by the manufacturing process. When you take into account variables such as increased fuel economy as a result of the use of lightweight 3D printed parts, the environmental advantages become even more significant.

- Taking Precautions

Three-dimensional printing (3D printing) helps a firm decrease its production risks because of the advantages of Quality and Consistency stated above. The use of 3D printing technology by product designers may allow them to evaluate product prototypes prior to making large-scale manufacturing investments that might prove to be disastrous.

Conclusion

3D printing offers several advantages in today’s technologically advanced society. With the assistance of 3D printing, you may even construct a huge house. 3D printing is only the beginning, and you should be aware that 4D printing is also on the horizon!!